Equipping your poultry farm?involves crucial decisions, especially regarding housing. Choosing the wrong?cage system?can lead to inefficiencies, higher operational costs, and management headaches. As experienced manufacturers, we guide you towards practical solutions like the reliable?A-type chicken cage.

A-type chicken cages?are a common?poultry housing system?where tiers of?cages?are arranged in a stepped, offset manner, resembling the letter ‘A’ in cross-section. This design allows?manure?to fall directly into a pit or onto dropping boards below, simplifying structure and often reducing initial investment compared to more complex systems like H-type?cages.

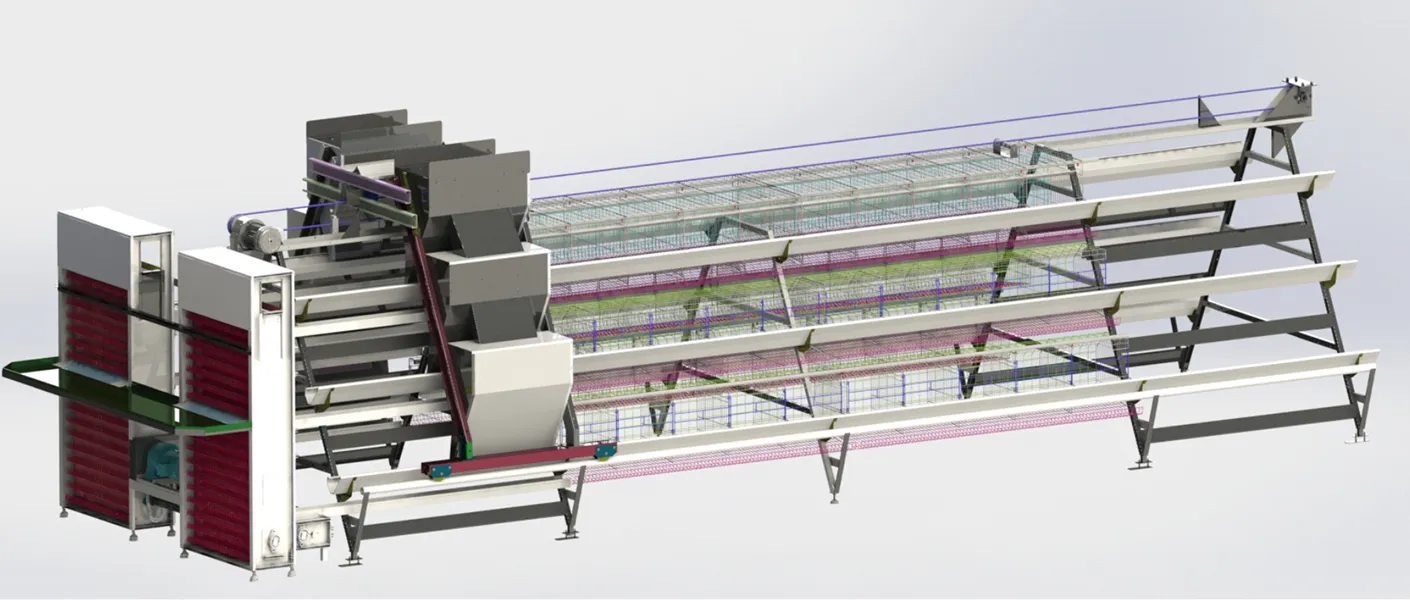

Big Herdsman Type A layer cage

Greetings from your dedicated partner in?livestock breeding equipment. As a manufacturing plant with extensive experience serving global leaders in?Poultry Production,?Egg Production, Pig Production, and Aquaculture Production, alongside engineering contractors and agricultural technology firms, we understand your priorities. You demand robust quality, technological reliability, exceptional service, and long-term value. Choosing the right?poultry housing system?is fundamental to achieving these goals.

Among the various?cage systems?available for?modern poultry farming, the?A-type chicken cage?remains a popular and highly relevant option for many operations worldwide. While perhaps less automated than its H-type counterpart, the?A-type cage system?offers distinct advantages in terms of initial cost, simplicity, and suitability for specific climates and management styles. This article will delve into the structure, operation, benefits, and ideal applications of?A-type chicken cages, drawing upon our hands-on experience in designing and manufacturing these essential pieces of?poultry farm equipment. Let’s explore why this tried-and-tested system might be the perfect fit for your?poultry?enterprise.

The defining characteristic of an?A-type cage system?is its unique tiered arrangement. Unlike H-type?cages?that stack directly vertically,?A-type cages?are offset. Imagine looking at the end of a row – the tiers step back and up, forming a shape similar to the letter ‘A’. Typically, these systems consist of 2, 3, or sometimes 4 tiers.

This stepped structure is fundamental to its design and operation. Each?cage?is constructed from durable materials, usually?hot-dip galvanized?steel wire?mesh, ensuring longevity and resistance to the corrosive environment of a?poultry house. The?cage frame, also typically made of?galvanized?steel, provides the necessary support for the multiple tiers of?cages. The floors of the?cages?are sloped, allowing eggs laid by the?hens?to gently roll forward to a collection area outside the?cage.

The key consequence of the ‘A’ shape is how?manure?is handled. Droppings from birds in the upper tiers fall?past?the lower tiers, directly onto dropping boards placed above the lower?cage?rows or, more commonly, into a pit excavated beneath the?cage?bank. This structural simplicity is a hallmark of the?A-type chicken cage system.

Manure management?is a critical aspect of any?poultry housing system, directly impacting air quality, bird health, and operational efficiency. In?A-type cage systems, the offset design dictates the primary methods of?manure?handling, which are generally simpler and less mechanically complex than those found in H-type systems.

Because?manure?from upper tiers falls directly downwards, it accumulates either:

Compared to the belt systems of H-type?cages,?A-type manure management?is generally less frequent but involves larger volumes when cleanout occurs (especially with deep pits). The emphasis is on structural simplicity rather than daily mechanical removal from under each?tier.

Feeding and watering systems?in?A-type chicken cages?are designed for reliability and efficient delivery to all birds, similar in principle to other?cage systems, but adapted to the A-type structure.

Big Herdsman layer cage

These systems, whether?automatic?or?semi-automatic, are designed to provide continuous access to feed and clean water, essential for maintaining the health and?productivity?of the?laying hens?housed in the?A-type cages. As manufacturers, we supply high-quality,?long-lasting?feeding and?drinking systems?compatible with our?A-type cage?designs.

While H-type systems often boast higher density and automation,?A-type chicken cages?offer several distinct advantages that make them a compelling choice for many?poultry?producers, particularly those mindful of initial investment and operational simplicity.

These advantages make?A-type cages?a practical and cost-effective solution for many small to medium-sized?egg production?facilities, or even larger ones in specific regions or operating models where the benefits of simplicity and lower initial cost outweigh the higher density offered by H-type?cages.

Understanding the key differences between?A-type?and?H-type cage systems?is essential for making an informed decision for your?poultry farm. They represent two distinct approaches to vertical?cage?housing.

| Feature | A-Type Cage System | H-Type Cage System |

|---|---|---|

| Structure | Offset/Stepped Tiers (‘A’ Shape) | Directly Stacked Tiers (‘H’ Shape) |

| Stocking Density | Lower to Moderate | Higher |

| Manure Handling | Deep Pit / Dropping Boards / Scrapers | Manure Belts under each tier |

| Manure Removal Freq. | Less Frequent (Pit) / More (Boards) | Frequent (Daily via belts) |

| Automation Level | Lower to High (Varies) | Typically Higher (esp. Manure) |

| Initial Cost | Generally Lower | Generally Higher |

| Building Height | Can suit lower buildings | Better utilizes taller buildings |

| Ventilation | Good potential for natural airflow | More reliant on mechanical?ventilation |

| Mechanical Complexity | Lower | Higher (Manure Belts) |

| Ideal Application | Budget-conscious, simpler ops, some climates | High-density, high-automation focus |

In essence:

As manufacturers of both systems, we help clients analyze their specific needs –?farm size, budget, labor availability, climate, and management philosophy – to determine which?cage system?offers the best fit.

An?A-type chicken cage system?is often the optimal choice under specific circumstances and for particular types of?poultry farm?operations. It’s not inherently “better” or “worse” than H-type; it’s about suitability. Consider?A-type cages?if:

Big Herdsman Type A layer cage

Ultimately, the decision involves weighing the trade-offs between initial cost, density, automation level, and management style.?A-type cages?remain a viable and efficient option for a significant portion of the global?poultry industry.

As with any significant investment in?poultry farm equipment, the quality of materials used in manufacturing?A-type chicken cages?is paramount to ensure durability, longevity, and a good return on investment. We prioritize robust materials designed to withstand the demanding environment of a?poultry house.

Inferior materials, such as electro-galvanized (cold galvanized) wire, will corrode much faster, leading to premature failure, potential bird injuries from broken wires, and the need for costly replacement. Investing in?A-type cages?made from high-quality?hot-dip galvanized?steel and durable auxiliary materials is crucial for long-term operational success. As a?poultry equipment supplier, we guarantee the use of?high-quality materials?in all our?cage systems.

While?A-type cages?are most commonly associated with?laying hens?for?egg production, variations of the design can sometimes be adapted for other phases of?poultry?life, although it’s less standard than floor rearing or specialized?cages.

While adaptable, the primary and most efficient use of the standard?A-type cage system?remains for housing?laying hens?during their production cycle. Specialized designs are needed for optimal?broiler?or?pullet?rearing in?cages. We manufacture specific?pullet cage systems?and?broiler farming equipment?tailored to their unique needs.

Investing in a quality?A-type cage system?is the first step; proper maintenance is key to maximizing its lifespan and ensuring it continues to support efficient?poultry production. Consistent upkeep prevents premature deterioration and maintains a healthy environment for your birds.

Key maintenance practices include:

Consistent maintenance, even for simpler?A-type systems, protects your investment, ensures the welfare and?productivity?of your?hens, and contributes to the overall smooth operation of your?poultry farm. As your?equipment supplier, we provide guidance on maintaining the specific?A-type cage systems?we manufacture.

Choosing the right partner to supply your?A-type chicken cages?is as crucial as selecting the system itself. For our target clients – large-scale producers, contractors, and service companies – reliability, quality, and support are non-negotiable.

Look for a?manufacturer and supplier?who demonstrates:

As a dedicated?livestock breeding equipment manufacturer?with a global footprint, we embody these principles. We don’t just sell?cages; we provide reliable, efficient housing solutions backed by expertise and a commitment to your farm’s success. Check our?About Us page?for more on our philosophy.

FAQs

How many chickens can be housed in a standard A-type cage set?

The capacity of a?set of cages?depends on the?cage?dimensions, the number of tiers, and the length of the row. Manufacturers provide specifications based on recommended stocking densities (e.g., cm2 per bird), which can vary by region and bird size. A typical 3-tier A-type cage?might hold 90-120 birds per unit section (e.g., 2 meters long), but total?poultry house?capacity depends on the number of rows and house length.

Is egg collection automated in A-type cage systems?

Egg collection?can?be automated in?A-type cage systems, although?semi-automatic?or manual collection is also common, especially in lower-cost setups. Automated systems typically use egg belts running along the front of the?cages?on each?tier, similar to H-type systems, which convey eggs to a cross-collection point.

What is the typical lifespan of an A-type chicken cage?

A well-maintained?A-type chicken cage?made from high-quality?hot-dip galvanized?steel can typically last 15-20 years, sometimes longer. Lifespan is heavily influenced by the quality of the galvanization, environmental conditions (humidity, ammonia levels), and maintenance practices.

Does the A-type system require mechanical ventilation?

While the open structure of?A-type cages?can lend itself better to natural?ventilation?than H-type, mechanical?ventilation?is still highly recommended, especially for larger commercial?poultry houses?and in climates with temperature extremes. Proper air exchange is crucial for removing moisture, ammonia, heat, and providing fresh air to maintain bird health and?productivity, regardless of the?cage system.

Are A-type cages cheaper than H-type cages?

Generally, the initial purchase and installation cost of an?A-type cage system?tends to be lower than a comparable H-type system, primarily because it lacks the complex under-cage?manure belt system required for H-type. However, total lifetime cost should also consider factors like building costs, potential labor differences for manure handling, and bird density.

Can A-type cages be used in cold climates?

Yes,?A-type cages?can be used in cold climates, but the?poultry house?must be well-insulated and equipped with an effective heating and mechanical?ventilation system?to maintain optimal temperatures and manage moisture, especially if using a deep pit?manure?system which can release moisture.

Key Takeaways:

The?A-type chicken cage system?remains a cornerstone of efficient?poultry farming?globally. Its blend of practicality, cost-effectiveness, and proven reliability makes it an excellent choice for many?egg production?operations. As your manufacturing partner, we are here to provide top-quality?A-type cages?and the expertise to help you make the best housing decisions for your?poultry farm.

Considering A-type cages for your facility? Contact us today for a detailed consultation, customized quotes, and to learn how our durable and efficient systems can benefit your poultry operation.